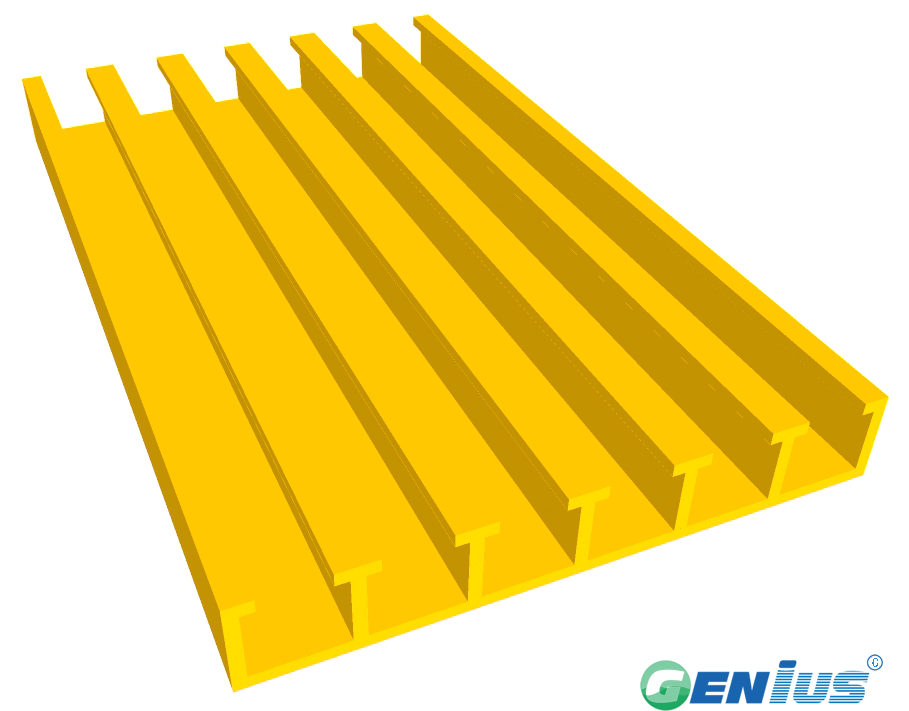

结构型材-甲板(间苯)

欢迎询价。

Genius FRP

FRP structural shapes profile is made of glass fiber reinforced material, resin as adhesive, glass fiber cloth as a package reinforcement layer, through the thorough penetration, in the metal mold heating, molding, curing, drawing in the traction machine pulled A new type of composite material, with good physical properties, widely used in high strength, large span Situation.

Varieties | Size(mm) | Weight(kg/m) | Size(in) | Weight(lbs/in) |

Deck | A*T1*B*T2 | A*T1*B*T2 | ||

| 305*6.4*47.5*6.4 | 8.5 | 12" x 1/4" x 15/8" x 1/4" | 18.7 | |

| 500*5*48.5*6.4 | 12 | 20" x 3/16" x 2" x 1/4" | 26.5 | |

| 500*5*40*5 | 9.8 | 20" x 3/16" x 25/16" x 3/16" | 21.6 |

Markets

Architectural

Bridge & Highway

Chemical

Food & Beverage

Manufacturing

Metals & Mining

Microelectronics

Oil & Gsa

Pharmaceutical

Power

Pulp & Paper

Recreation

Telecommunications

Transportation

Water & Wastewater

The characteristics:

Corrosion Resistant

Low Maintenance

Fire Retardant

Low Install Cost

Heavy Metal Safe

Long Service Life

Electrically & Thermally Non Conductive

High Strength-to-Weight Ratio

Introduction of raw materials——Resin type

Code | Resin type | Flame retardant property | Recommended usage occasions |

VEFR-25 | Vinyl type | Oxygen index 28 or above | Acid, alkali and other corrosive harsh environment |

IFR-25 | Meta benzene | Oxygen index 28 or above | A VEFR type economy, and excellent, moderate acid alkali and solvent |

OFR-25 | Ortho type | Oxygen index 28 or above | General acid and alkali environment |

Application:

Genius© pultruded fiberglass structural shapes from Genius Composite Inc. are used in a wide range of applications and provide a unique combination of corrosion resistance, high strength, dimensional stability and light weight, along with thermal and electric non-conductivity. Durable Genius shapes provide years of low maintenance service in areas where steel, aluminum or wood components are traditionally specified. Today ,these shapes are often used in highly corrosive applications where stainless steel and other expensive components were once required.

Genius Shapes

Mechanical Properties | ASTM | Units | Value | Units | Value |

Tensile Stress, LW | D-638 | psi | 30000 | kgf/m² | 21092086 |

Tensile Stress, CW | D-638 | psi | 7000 | kgf/m² | 4921487 |

Tensile Modulus, LW | D-638 | 10^6psi | 2.5 | 10^6kgf/m² | 1758 |

Tensile Modulus, CW | D-638 | 10^6psi | 0.8 | 10^6kgf/m² | 562 |

Compressive Stress, LW | D-695 | psi | 30000 | kgf/m² | 21092086 |

Compressive Stress, CW | D-695 | psi | 15000 | kgf/m² | 10546043 |

Compressive Modulus, LW | D-695 | 10^6psi | 2.5 | 10^6kgf/m² | 1758 |

Compressive Modulus, CW | D-695 | 10^6psi | 1 | 10^6kgf/m² | 703 |

Flexural Stress, LW | D-790 | psi | 30000 | kgf/m² | 21092086 |

Flexural Stress, CW | D-790 | psi | 10000 | kgf/m² | 7030695 |

Flexural Modulus, LW | D-790 | 10^6psi | 1.8 | 10^6kgf/m² | 1266 |

Flexural Modulus, CW | D-790 | 10^6psi | 0.8 | 10^6kgf/m² | 562 |

Modulus of Elasticity | Full Section | 10^6psi | 2.8 | 10^6kgf/m² | 1969 |

Shear Modulus | --- | 10^6psi | 0.45 | 10^6kgf/m² | 316 |

Short Beam Shear | D-2344 | psi | 4500 | kgf/m² | 3163813 |

Punch Shear | D-732 | psi | 10000 | kgf/m² | 7030695 |

Notched Izod Impact,LW | D-256 | ft.-lbs./in. | 25 | kg/m | 3.46 |

Notched Izod Impact,CW | D-256 | ft.-lbs./in. | 4 | kg/m | 0.55 |

Excludes Round Rod and Square Bar

Physical Properties | ASTM | Units | Value |

Barcoal | D-495 | --- | 45 |

24 Hour Water Absorption | D-570 | %max | 0.45 |

Density | D-792 | lbs./in.³ | 0.062-0.07 |

Coefficient of Thermal Expansion,LW | D-696 | 10^-6in./in./℃ | 8 |

Flammability Properties | ASTM | Units | Value |

Tunnel test* | E-84 | Flame Spread | 25 max |

Flammability* | D-635 | --- | Non-Burning |

Electrical Properties | ASTM | Units | Value |

Arc Resistance,LW | D-495 | seconds | 120 |

Dielectric Strength,LW | D-149 | kv./in. | 35 |

Dielectric Strength,PF | D-149 | volts/mil | 200 |

Dielectric Constant,PF | D-150 | @60hz | 5 |

LW=Lengthwise, CW=Crosswise,PF=Perpendicular to Laminate Face

*Pertains to ISOFR and VEFR only

简体中文

简体中文

English

English